When people think about surveillance technology, they picture what’s most visible: cameras in train stations, traffic monitoring in smart cities, or patrol bots in public spaces. What they rarely picture is a commercial kitchen, a loading dock behind a supermarket, or the sterile corridor of a food processing plant.

But these are precisely the environments where surveillance, when done right, can save lives.

Food Safety Isn’t Optional. It’s Critical.

The consequences of food safety failures are often severe and sometimes irreversible. In recent years, multiple high-profile cases around the world have highlighted just how quickly things can go wrong. It could be a tragic death linked to lapses at a restaurant, through to widespread food poisoning incidents affecting families and festival-goers.

It can also affect businesses, too. Many businesses around the world pay for catering for their staff. When a mass outbreak of food poisoning occurs, not only is the staff’s health at risk, but the business’s productivity suffers.

Essentially, there are many areas where food is handled and distributed, and it is increasingly common to find lapses in health best practices, or even regulation.

When foodborne illness strikes, it’s not just public health at stake—it’s trust, reputation, and in many cases, the future of a business. Regulatory penalties, civil lawsuits, and irreversible brand damage follow closely behind. For any business in the food supply chain, from central kitchens to quick-service restaurants, compliance is not a checkbox. It’s also a lifeline.

The Reality of Enforcing Food Safety in Practice

But enforcing food safety compliance isn’t easy. Internal audit teams or inspectors from government food agencies often have just one or two days on-site. During this time, employees typically present their best behaviour, fully aware that they’re being observed. It’s compliance by performance, not habit.

It’s also very easy to simply overlook or become complacent until a problem occurs. In one stunning example, 73 out of 211 people that ate at a restaurant fell ill. It was subsequently found that there were strains of Salmonella in the food preparation areas, and that seven of the 34 food handlers had not been properly registered. No one was aware of this until the investigation after the event.

Compounding the problem is the complexity of food regulations. There are countless protocols across hygiene, temperature control, PPE usage, and cross-contamination prevention. There are far too many of these regulations for any human inspector to enforce comprehensively, especially in dynamic, high-pressure environments like central kitchens.

Traditional rule-based monitoring systems aren’t much better. They rely on fixed parameters and pre-trained models, meaning every new use case demands fresh data, re-training, and expensive implementation. They don’t adapt. They don’t understand context. They don’t behave like a person would.

This is Where SenTRACK Comes In

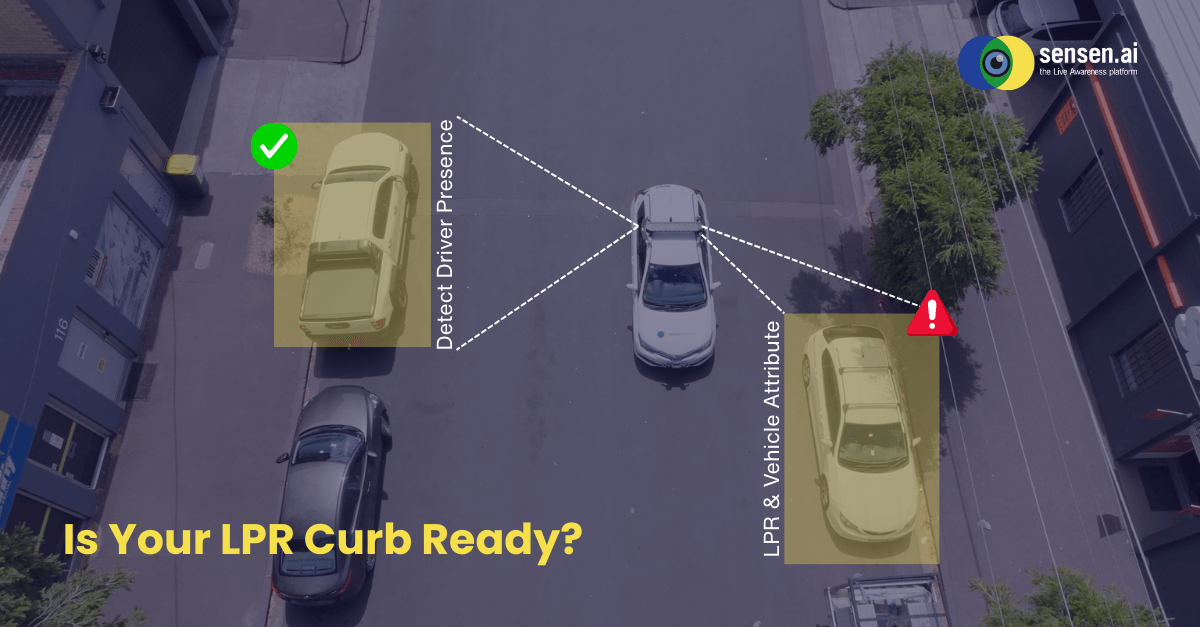

SenTRACK isn’t just a camera system. It’s a real-time AI-powered operational assistant. Designed to act like a trained food safety officer, it continuously interprets visual cues, detects breaches, and responds with judgment. It understands context, urgency, and role-specific responsibilities, and acts immediately.

SenTRACK sees it, and then flags it in real time. With video evidence, contextual tagging, and alerts customised to your protocols.

For example:

- Was a surface left uncleaned between shifts?

- Did a staff member skip handwashing after using the restroom?

- Was PPE missing in a raw food prep zone?

- Did someone collapse from heat exposure near a fryer?

Beyond Surveillance: Intelligent Role-Based Compliance

Unlike conventional systems that rely on fixed rules, SenTRACK is powered by vision-language models (VLMs) and integrated with large language models (LLMs). This gives it the flexibility to understand the responsibilities tied to specific roles, like a food safety officer or site manager, and act accordingly, without needing pre-programmed rules for every scenario.

This allows food businesses to:

- Instantly modify compliance criteria using natural language prompts

- Detect non-obvious patterns, such as fatigue-related behaviours or workflow bottlenecks

- Search incident archives using everyday language: “Show me all hygiene breaches in Zone B over the past week”

- Avoid false positives by accounting for context and intent

The result is powerful, but elegant: A system that behaves like a human, but without the limitations of time, memory, or presence.

Transforming the Entire Food Ecosystem

SenTRACK is already helping to transform operations across the entire food value chain:

- Central Kitchens & Processing Plants: Automate QA checks, enforce hygiene standards, and ensure staff safety around hazardous equipment.

- Quick-Service Restaurants: Prevent accidents, streamline cleaning workflows, and manage high foot traffic zones more safely.

- Cold Chain Logistics: Track time-sensitive deliveries, monitor loading dock conditions, and verify cold storage integrity with visual evidence.

- Retail & Supermarkets: Detect non-compliant handling in delis, monitor temperature zones, and assist in customer safety near wet floors or cluttered aisles.

Wherever food is stored, prepared, or served, SenTRACK ensures it’s done safely.

From Reactive to Proactive: Redefining Compliance

Historically, compliance has been reactive. Breaches are only addressed after they occur, and this is often too late. Investigations drag. Accountability blurs. Prevention fails.

SenTRACK changes that. It brings proactive performance into the picture. Teams can review real-time footage for training. Safety protocols can be enforced automatically. Investigations take minutes instead of days. And staff can work confidently, knowing the system is there to support, but not spy on, them.

In industries governed by strict codes like HACCP, FSANZ, and FDA regulations, this shift isn’t just valuable. It’s essential.

Smarter, Safer, and More Human

SenTRACK doesn’t just observe. It learns. With every interaction, its AI becomes sharper, more context-aware, and better aligned to your unique operations. If you change a rule, or redefine a risk profile, it adapts immediately. No retraining. No delay.

That’s what makes it different. That’s what makes it human-like in a way traditional systems never could be.